The “Member Spotlight” series highlights the individuals that make our organization great. Each post tells the story of an outstanding Mass Energy or PP&L member. By sharing their stories we hope to spread the word about their unique efforts and inspire others to follow in their footsteps.

Meet Susanne Altenburger, New England GreenStart member since 2009 and long-time energy efficiency expert. As she explains “there is a certain philosophy behind the price you pay when you have bad habits.” Eliminating these energy “bad habits” through efficiency is key for Susanne. After researching the fundamentals of and determining what low-carbon construction is all about, she found that many of us spend way too much money on wasted energy. By minimizing her wasted energy and greening up the small amount of energy she does use with Mass Energy, Altenburger has forged a model energy lifestyle.

Meet Susanne Altenburger, New England GreenStart member since 2009 and long-time energy efficiency expert. As she explains “there is a certain philosophy behind the price you pay when you have bad habits.” Eliminating these energy “bad habits” through efficiency is key for Susanne. After researching the fundamentals of and determining what low-carbon construction is all about, she found that many of us spend way too much money on wasted energy. By minimizing her wasted energy and greening up the small amount of energy she does use with Mass Energy, Altenburger has forged a model energy lifestyle.

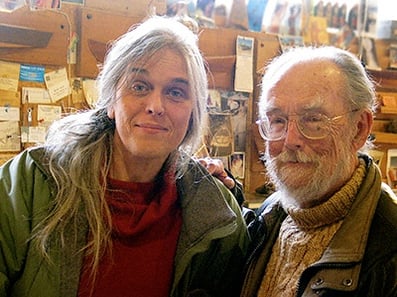

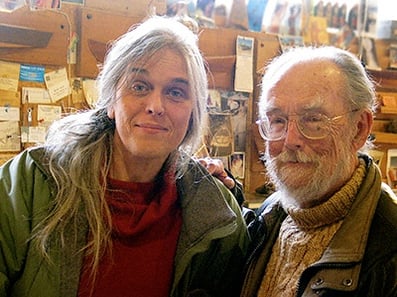

Susanne Altenburger moved from Germany to the United States as a student. She moved to Boston in 1990 and met her husband Phil Bolger, a prolific and highly regarded recreational boat designer, which began her career in naval architecture. Together they lived in Gloucester and worked at Phil Bolger & Friends Inc. designing highly efficient, low- maintenance fishing boats and military landing craft utility boats.

Up until 1999, Susanne and Phil lived on a boat) with an office on land. However, the need for more space convinced them to buy a house in which they could live and work. They found a small two-story, electrically heated house in need of renovations and together they agreed to create a low-carbon home in the most cost-effective and energy-efficient way possible. Altenburger explains that “if you try to help folks with their bills, a lot of it has to do with hardware.” So, their journey began and for the next ten years, they transformed their high-carbon home to a low-carbon one.

Altenburger and Bolger focused on insulation to improve the home’s efficiency, especially because most of their electricity-consumption would be from heating. Built in the 1970s, the home’s standard 4” walls were satisfactory, but the insulation was woefully inadequate. So they “super-insulated” the existing structure by adding a non-supporting 2x4” stud wall roughly four inches inside the structural outside wall along every room’s exterior.

From there they installed 12” of R-40 fiberglass insulation in the outside walls of the house. They covered this with a thick polyethylene vapor-barrier to keep moisture and fiberglass-chemicals from spreading. In the attic, they installed R-60 insulation and ran the water pipes inside of the insulation to prevent winter freezing. And finally, to introduce some “thermal mass”, they added two layers of 5/8” dry-wall to close in the now 12+” thick wall which would absorb and maintain the rooms’ temperature at a constant level throughout the year. Because the home doesn’t lose much heat, the design of the house made it possible to maintain the indoor temperature at a constant 63 ° F without having to actively adjust.

For the studs of the inside wall, labor, insulation, vapor-barrier and dry-wall, it was possible to limit the cost to $10,000 because Altenburger and Bolger did most of the construction themselves. They pulled the electrical outlets inwards, stapled on the vapor-barrier, and hung the dry-wall. They hired someone to tape and smooth the seams and then finish it with a coat of paint. They also spent $1000 on installing an Air-to-Air Heat-Exchanger which circulates air with one fan to draw out stale air while another fan pulls fresh air indoors.

Altenburger and Bolger’s efforts were all low-tech, permanent, and affordable. As Susanne explains it, they “chose a plain-vanilla, low-cost, non-exotic approach”. Her advice to anyone considering ways to reduce their house’s carbon-footprint:

“First, take care of [the major heat-loss challenges] to arrive at a super-insulated and on-demand-ventilated house. Second, with a super-insulated house, you can go with much smaller heating and cooling systems, including recycling the old resistance-heater units, and keeping the now superfluous extra capacity as ‘spares’. Third, examine the return on investment with e.g. a heat-pump which could double as an air-conditioning unit. Fourth, invest in renewables such as photovoltaics either on your property, or by share in a dedicated facility. And finally, get whatever remains of your electricity needs from a certified-sustainable source such as MASS ENERGY.”

Everyone can make environmentally and economically sound decisions and we’re constantly inspired by people like Altenburger. Altenburger and Bolger demonstrated the success of super-insulating their home. In addition to the changes they made to their home, they also green their electricity with locally sourced renewable energy through Mass Energy’s New England GreenStart program. With energy efficiency and sustainable energy sourcing working side-by-side in our homes, low-carbon living is most definitely attainable.

~ Puanoa A. Higginson

Comments